Environmental Impact of Sulfuric Acid Leaching

The electro-winning system [SX-EW] is a step in the right direction as the mining industry attempts to develop methods that have less of an impact on the environment. Really, it's a huge step since it eliminates tailings impoundments, which are unsightly and can cause water pollution, and smelting, which can cause air pollution. It only works on oxide ore, whereas the majority of the ore at Rosemont is sulfide and will not dissolve into solution in a reasonable period of time. Therefore, leaching can be used on some 14% of the ore, or approximately 59 million tons.

Sulfuric acid, the leaching agent, is brought on site in large tankers. The sulfuric acid is diluted and sprayed or dripped over oxide ore, which dissolves the oxidized minerals completely in the solution. The solution, “pregnant” with the dissolved metals, is then piped to the SX-EW plant that separates out the copper into 99% pure bars. The copper is ready with no need for smelting. The waste solution is piped to on-site holding ponds, which are securely lined, awaiting the next load of oxide ore to be placed on the leach pads.

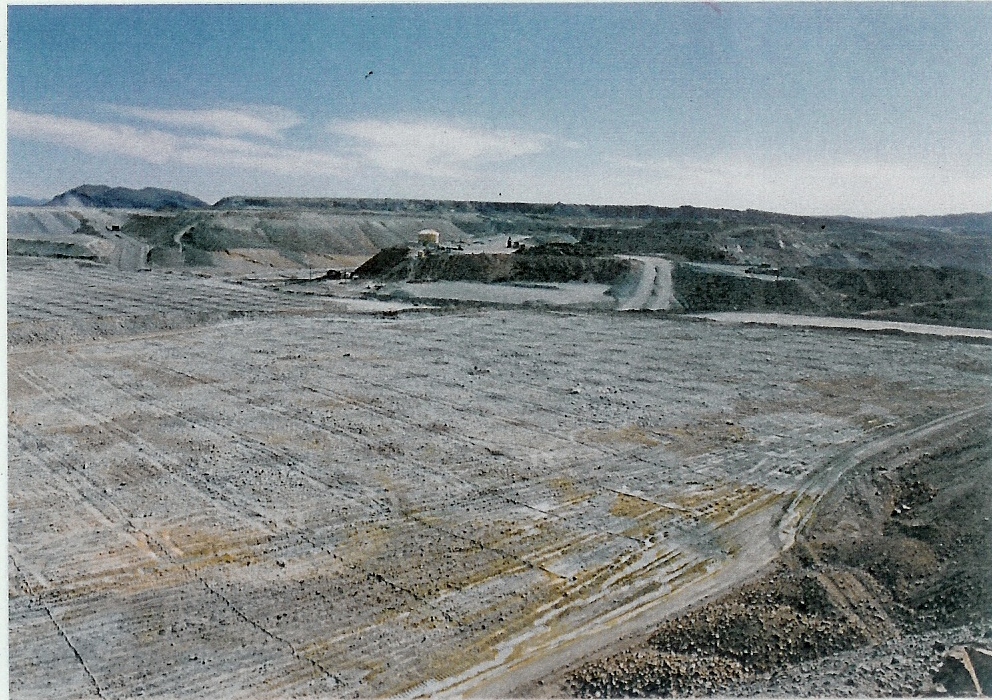

Pads for Leaching Ore with Sulfuric Acid

Ideally, this system is a closed circuit and is considered environmentally safe. However, there are two conduits to environment impact. First, the leach solution is stored in open ponds (until the mine is closed then it is put in barrels and taken to toxic waste dumps). Second, the leach solution and the sulfuric acid can spill as they are piped around the facility. There is data to show that these spills impact groundwater—even two miles away.

1) Toxic Ponds:

As the leach solution is reused, the unwanted metals concentrate into a very toxic solution, which sits out in open ponds, waiting to be piped back to be sprayed on fresh ore on the leach pads.

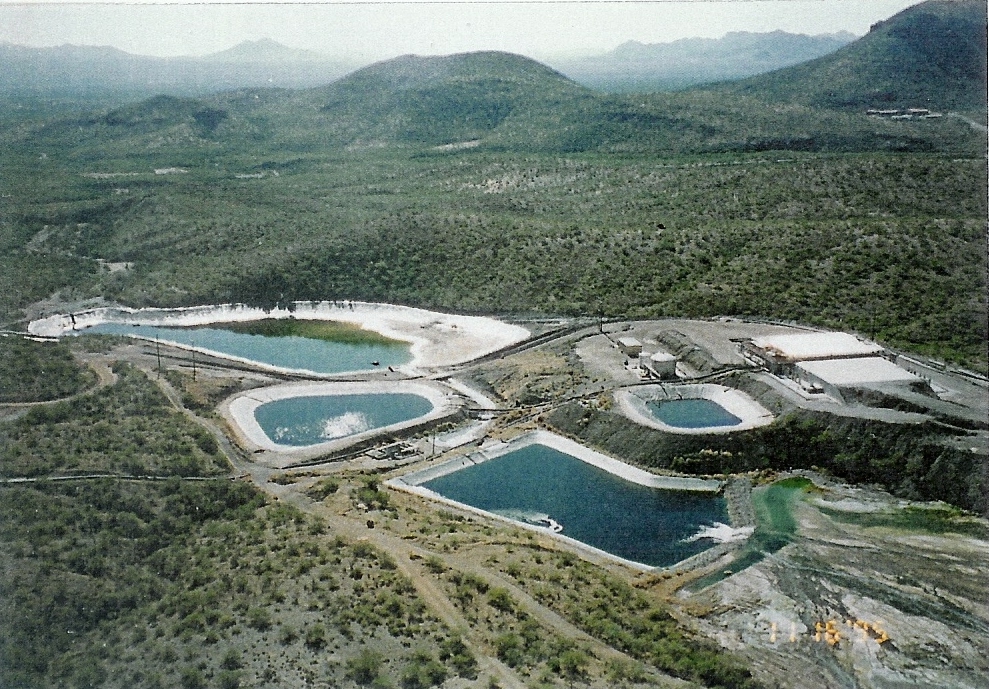

Holding Ponds for Leach Solution

The data on the table on the following page shows the "Characteristics of Leach Solution, which is a toxic hazard. Whereas these ponds are an inevitable part of mining and are considered to be an improvement over tailings impoundments, it is questionable if they are appropriate for a National Forest setting with its requirements for beneficial use.

Characteristics of Leach Solution in Named Ponds at Sierrita Mine

(Metals measured in mg/ltr)

Facility/Sample Location |

Headwall No.1 |

Bailey Lake |

B-Pond |

Headwall No. 3 |

Headwall No. 5 |

Duval Canal |

SX-3 Pond |

SX-1 Pond |

SX-1 |

Reclaim Pond |

D-Pond |

Headwall No. 2 |

Date Sampled |

4/22/98 |

4/22/98 |

4/22/98 |

4/22/98 |

4/22/98 |

9/15/98 |

4/15/99 |

4/15/99 |

4/15/99 |

4/15/99 |

6/30/98 |

9/28/98 |

Conductance (umhos/cm) |

14,800 |

16,300 |

8,270 |

13,100 |

5,040 |

2,425 |

|

629 |

104,000 |

3450 |

2540 |

25,940 |

pH, lab |

2.2 |

2.1 |

3 |

2.4 |

4.3 |

6.9 |

1.8 |

7 |

1.4 |

10.4 |

6.3 |

2.4 |

Total Dissolved Solids |

47,600 |

47,500 |

15,900 |

41,200 |

9.890 |

2140 |

3870 |

629 |

37,000 |

3270 |

2270 |

48,000 |

Sulfate |

15,300 |

23,000 |

9280 |

24,100 |

5600 |

1220 |

3310 |

190 |

35,600 |

1820 |

1240 |

31,100 |

Arsenic |

0.15 |

0.15 |

0.13 |

<0.1 |

0.08 |

ND |

0.03 |

0.06 |

ND |

0.052 |

0.049 |

ND |

Calcium |

526 |

522 |

667 |

570 |

518 |

541 |

125 |

68.3 |

141 |

645 |

432 |

533 |

Magnesium |

3,740 |

3680 |

1380 |

3580 |

1070 |

82.9 |

95.1 |

9 |

176 |

0.5 |

32.4 |

3570 |

Sodium |

400 |

405 |

383 |

440 |

393 |

144 |

98.4 |

60.9 |

147 |

276 |

53.1 |

435 |

Potassium |

55 |

65 |

11 |

45 |

17 |

38.9 |

19.2 |

|

490 |

59.3 |

19.2 |

52 |

Chloride |

3340 |

3540 |

2050 |

3470 |

51 |

92 |

140 |

16 |

620 |

320 |

170 |

3090 |

Fluoride |

270 |

260 |

78 |

200 |

60 |

1.4 |

6 |

0.9 |

240 |

1.3 |

1.5 |

200 |

Nitrate |

5.5 |

6.8 |

0.03 |

9.4 |

250 |

1.58 |

2.38 |

|

3.6 |

2.23 |

0.33 |

11 |

Beryllium |

1.08 |

1.06 |

0.312 |

0.98 |

0.81 |

0.01 |

0.0008 |

0.0008 |

0.03 |

ND |

ND |

0.882 |

Cadmium |

1.05 |

1.17 |

0.522 |

1.02 |

0.133 |

0.015 |

0.0181 |

0.0022 |

0.0392 |

0.014 |

0.046 |

1.11 |

Chromium |

1.4 |

1.1 |

0.1 |

0.9 |

ND |

ND |

0.36 |

ND |

ND |

ND |

ND |

1 |

Cobalt |

10.5 |

10.7 |

3.6 |

9.5 |

1.47 |

0.06 |

0.21 |

ND |

15.3 |

ND |

ND |

10.1 |

Copper |

|

|

|

|

|

3.2 |

845 |

55.3 |

5700 |

|

0.51 |

|

Iron |

743 |

710 |

282 |

411 |

0.13 |

49.9 |

49.5 |

2.72 |

342 |

ND |

0.23 |

612 |

Lead |

0.012 |

0.023 |

0.015 |

0.021 |

0.006 |

0.136 |

0.0627 |

0.041 |

0.298 |

ND |

0.002 |

ND |

Manganese |

486 |

501 |

227 |

465 |

60.6 |

6.65 |

9.27 |

0.35 |

23.1 |

ND |

2.53 |

476 |

Molybdenum |

1.2 |

1 |

>0.5 |

0.8 |

0.25 |

0.6 |

0.26 |

0.07 |

2 |

3.71 |

11.3 |

|

2) Records of spills and their impact on groundwater

Spills at Sierrita Mine (date order with most recent first)

All spills were on-site in mill region, principally due to broken pipes. Leach solution content varies according to the step of the process, as is seen by table above.

Date of spill |

Amount of Spill |

Content of Spill |

4/19/03 |

8,722 lbs. |

Sulfuric acid |

1/31/02 |

39,375 gals. |

Sulfuric acid |

7/3/01 |

1,209 lbs. |

Sulfuric acid |

5/22/00 |

5,350 gallons |

Leach Solution* |

5/05/98 |

40,000 gallons |

Leach Solution* (includes copper) |

5/04/98 |

120,000 gallons |

Leach Solution* (includes copper) |

7/11/97 |

2,798 lbs |

Sulfuric acid |

3/29/97 |

8,000 lbs |

Sulfuric acid-93% |

8/11/96 |

100 gallons |

Sulfuric acid |

7/22/96 |

3,000 lbs |

Sulfuric acid |

6/12/96 |

13,263 lbs |

Leach Solution (spent) |

3/23/96 |

3,000 lbs |

Sulfuric acid |

2/21/96 |

1,850 lbs |

Leach Solution* |

1/10/96 |

2,000 lbs |

Sulfuric acid |

1/8/96 |

4,000 lbs |

Sulfuric acid |

12/19/94 |

5,000 gallons |

Leach Solution* |

11/03/94 |

7,000 gallons |

Sulfuric acid |

9/19/90 |

2,000 gallons |

Diesel fuel |

3/16/90 |

1,500 gallons |

Hydrochloric acid |

9/8/88 |

10 gallons |

PCB’s |

9/6/88 |

10 gallons |

PCB’s |

See actual reports at www.savethesantacruzaquifer.info/Hazardous Material Incident Sierrita.htm

Spills at Bagdad Operations

Since Bagdad operations did not have a railway to the site, the chemicals and copper concentrate had to be trucked in and out of the milling/leaching area. There was a mountainous road that contributed to a number of truck accidents.

Bagdad operation is using an alternative route at this time.

Date of Spill |

Amount of Spill |

Content of Spill |

Owner of Property |

12/07/04 |

7,484 lbs |

Leach Solution |

On-site |

9/10/04 |

354 gals |

Sulfuric Acid |

On-site |

12/04/00 |

<200 gals |

Sulfuric Acid |

State Trust |

9/18/00 |

5,850 gals |

Xanthate (flotation chemical) |

Federal |

3/11/99 |

? |

Cyanides, Acids |

Federal |

3/07/99 |

12,000 gals |

Effluent (treated ww) |

Federal |

3/01/99 |

200 gals |

Sulfuric Acid |

State |

2/21/99 |

misc |

Glacial Acetic, Nitric Acid |

Federal |

7/27/98 |

? |

Sulfuric Acid |

State |

1/01/98 |

50,000 lbs |

Copper Concentrate |

State |

12/12/97 |

40,000 lbs |

Copper Concentrate |

State |

9/17/97 |

7/7200 lbs |

Sulfuric Acid |

On-site |

6/11/97 |

50,000 lbs |

Copper Concentrate |

Bagdad town |

3/09/97 |

1,500 lbs |

Sulfuric Acid |

On-site |

7/18/96 |

3.57 lbs |

Mercury |

Bagdad town |

6/18/96 |

3/40,000 lbs |

Copper Concentrate |

State/Private |

8/31/95 |

35,000 lbs |

Copper Concentrate |

State |

7/21/95 |

48,100 lbs |

Lead Sulfide/Cu Conc. |

County |

11/22/94 |

2,100 gals. |

Diesel |

County |

3/02/94 |

60 gals |

Sulfuric Acid |

State |

6/11/93 |

600 gals |

Sulfuric Acid |

State |

5/26/93 |

200 gals |

Diesel |

Private prop |

2/22/92 |

1,200 gals |

Sulfuric |

On-Site |

5/09/91 |

? |

Sodium Cyanide |

State |

9/18/90 |

13 gals |

PCB |

On-Site |

12/17/87 |

1,500 gals |

Sulfuric Acid |

State |

11/09/87 |

2/2,500 gals |

Sulfuric Acid |

State |

9/20/86 |

50-60 gals |

Sulfuric Acid |

State |

See actual reports on www.savethesantacruzaquifer.info/Hazardous Material Incident Bagdad.htm